Products

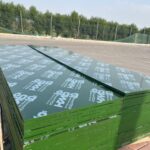

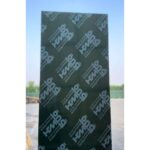

Plywood

Description: Film-faced plywood stands out for its hygienic surface and is resilient against potent detergents, making it a crucial choice for agricultural construction. Its lightweight nature, resistance to corrosion and water, ease of integration with other materials, and simple maintenance and cutting processes highlight its versatility. The edges treated with waterproof paint enhance its water and wear resistance, making it ideal for open construction environments such as warehouses, railway wagons, truck floors, and sidewalls. The application of high-quality imported films guarantees hardness and damage resistance, enabling its use in challenging conditions like temperature fluctuations, exposure to moisture, and frequent detergent cleaning. Moreover, Film Faced Plywood serves as a formidable barrier against termite attacks, ensuring long-lasting durability in diverse settings.

Common Uses: It is used in construction for moldings, panels, and roofing applications.

Names: Plywood Film Faced Boards, Marine Plywood, Shuttering Plywood, green plywood for Construction, Contracting. Origin: Indonesia, Malaysia, China, Russia.

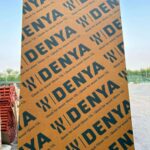

Commercial Plywood

Description: Commercial plywood is a versatile wood product widely used in construction and various applications. Typically, it is manufactured from multiple layers of wood veneers, with each layer known as a ply. These layers are glued together with the grain direction of adjacent plies perpendicular to each other, providing stability and strength. The number of layers can vary, and the quality of commercial plywood depends on the type of wood used and the manufacturing process. The face and back veneers of commercial plywood are usually made from high-quality wood for a more appealing appearance. Commercial plywood is known for its uniform look, making it suitable for a variety of applications where a smooth and consistent surface is desirable. The layers are often sanded for a smooth finish.

Common Uses:

Construction: Used in construction for applications such as formwork, panels, and roofs.

Interior Design: Popular for applications like wall panels, doors, and partitions.

Packaging: Often used in packaging materials due to its strength and durability.

DIY Projects: Its versatility makes it a common choice for various do-it-yourself projects.

Names: Plywood Film Faced Boards, Marine Plywood, Shuttering Plywood, green plywood for Construction, Contracting. Origin: Indonesia, Malaysia, China, Russia.

Squares Soft White Wood

Description: Spruce or pine wood squares from this region are likely to be popular for general construction and crafting purposes. s known for its high-quality European oak. Oak wood squares from Austria are likely to be durable and feature a distinctive grain pattern. European oak is often chosen for its strength and aesthetic appeal.

Common Uses: Construction framing, DIY projects, and basic woodworking.

Names: Spruce Softwood, White Wood, White Spruce. Origin: Austria, Romania.

White Wood Lumber

Description: The heartwood of Scots Pine exhibits a light reddish-brown hue, while the clearly defined sapwood takes on a pale yellow to nearly white color. Scots Pine boasts an extensive geographic distribution, ranging from Portugal in the west to the far reaches of eastern Siberia. As a result of this broad habitat, there exists a considerable natural diversity in terms of density, strength, size, and visual characteristics. This diversity stems from the wide array of growth conditions experienced by the tree. Notably, trees from colder northern climates tend to yield wood with higher density and finer texture due to their slower growth rates.

Common Uses: Construction framing, DIY projects, and basic woodworking.

Names & Types: Swedish White Wood, Building Wood, latazana. Origin: Sweden, Finland and Romania.

Tie Wires:

Modo Tie Wire | (S22) 6 kg |

Iron Tie Wire (collar) | 5/8 cm |

Clamps:

RAPID CLAMP | 40*50 |

Clamp | 80cm |

Clamp | 120cm |

Iron clamp | 80 cm |

Iron clamp | 120 cm |

Iron Clamp | 100 cm |

Tie Rod:

Tie rod Rose | 16MM*3M |

Tie rod Skewer | 16MM*6M |

Samuel Tie rod | 16MM |

Nails:

Nail | 6 cm 4 kg |

Solid steel nail | 50mm No. 22 |

Iron Nails – Saudi Alfakher | 5 cm wire, 3 kg |

Accessories

Description: Types of Steel Used in Construction:

Structural Steel: Widely used for beams, columns, and other load-bearing members due to its high strength.

Rebar (Reinforcing Steel): Embedded within concrete to enhance its tensile strength.

Sheet Metal: Used for roofing, cladding, and various architectural elements.

Properties:

Strength: Steel is renowned for its high tensile and compressive strength.

Durability: Resistant to environmental factors such as moisture and corrosion.

Versatility: Can be fabricated into various shapes and sizes.

Common Uses:

Frames: Structural steel frames provide support for buildings.

Concrete Reinforcement: Rebar reinforces concrete structures.

Roofing and Cladding: Sheet metal is commonly used for roofing and cladding.

Names & Types: Building Materials, Accessories. Origin: Saudi

Why Us?

We stand out in the wood and building materials trading market because of our experience and sustainability. We are dedicated to achieving our goals and meeting the expectations of our clients by offering over 20 types of high-quality and professional products. We understand that quality and excellence in service are the keys to our success and sustainable growth.

Recognizing the importance of building strong and enduring relationships with our clients and business partners, we aim to be true partners in their success. Through our dedication and commitment to achieving our clients’ objectives, we deserve to be recognized as a symbol of exceptional excellence, especially as we deal with internationally accredited brands.